Ibukijima island produces the highest class of “Iriko (dried Japanese anchovy),” which is the material for making broth. Since the fishing grounds are nearby, anchovies can be processed in a short period of time while still being very fresh after being caught. So Iriko produced on Ibukijima Island is the standard in high-end restaurants in the Western Japan.

Although the island is small, the total anual sales of Iriko in the island reached at 2 billion Japanese yen in high years, 800 million Japanese yen in low years, and 4 billion Japanese yen in 1980 at the highest. Dozens of fishermen bosses hire locals and people outside the island. The island has an unwritten rule that sales of Iriko are divided equally between fishermen boss, workers, and expenses. As sales increase, wages of workers increase. At its peak, the monthly salary exceeded 1 million Japanese yen. That is why the islanders own many houses on the island and on the mainland. When the whole family worked under a fisherman boss, they could built their house by one year labor. In the past, Iriko fishing lasted until winter. Now it is only allowed from June to September due to the protection of fishing resources. Sales have declined due to the short fishing season and the effects of global warming. In 2022, due to the poor catch in other regions, the transaction price of Ibukijima Island soared, resulting in sales for the first time in 20 years.

Fishing ships depart at 5:30 in the morning in June and July and at 6:00 in August. At the same time as the departing time comes, the ships leave together from the port to the newly dawned sea.

It is called "Patch Net Fishing." Because the shape of the net resembles a bifurcated patch. Two ships are paired. When they arrive at the fishing grounds, they hold the wire attached to the tip of the nets and move about 100 to 200 meters apart. A net spread out in the sea between the two ships slowly moved in the opposite direction of the school of fish swimming toward the sun, and the fish enter the net. After about 30 minutes, the two ships are combined and pull up the nets. The anchovies bouncing pit-a-pat emerge. They repeat this process until near sunset.

A high-speed carrier transports anchovies landed at sea to the island where the processing plant is located. The fish is sucked up from the ship with a hose, sorted into baskets, boiled for 4-5 minutes, and dried in a drying room for 3-12 hours depending on size. As soon as Iriko production finishes, other ship takes to the fish market that the Ibuki Fishery Cooperative owns in Kanonji Port on the mainland to put up for auction.

In the summer, Ibukijima island is very busy on the ship and at the processing plant. Some natives, who worked outside the island, said that they didn't return to the island during the Bon festival (the traditional summer ceremony to visit their ancestors tombs) because they were called out for help as soon as they returned to their homes. Iriko fishing was a lucrative work. However, everyone didn't necessarily want to do because it was hard work.

The dried Japanese anchovies (Iriko) are soaked in water and rest for about half a day to make broth. Original Iriko have a slight bitter taste, so it is better to remove the head and internal organs to make an elegant and gentle broth. I am practicing that, but, in a recent newspaper article, the owner of a top-class Japanese restaurant who used local ingredients talked that he did not remove the heads or internal organs of Iriko to create complicated taste with bitterness in his cooking. Whoops!.

Japanese anchovy fishery

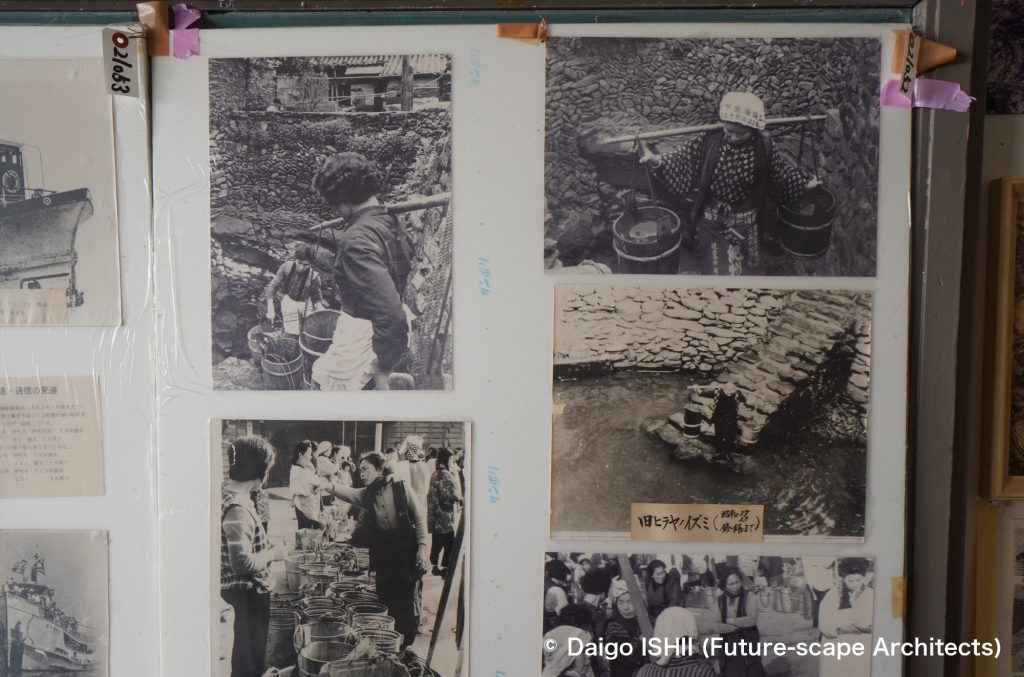

Processing

Landscape of Japanese anchovies processing plants

Iriko-meshi rice

Click here for your impressions

reference

"伊吹島の民俗 : 香川県観音寺市伊吹町 : 特集号"(香川民俗学会,1991)

伊吹島民俗資料館

"苦味、命の恵み"(日本経済新聞2023年4月30日朝刊,日本経済新聞社,2023)

Please do not use or upload our photos without permission.